What is Training Within Industry (TWI)?

Training within Industry (TWI) is a methodology that quickly and consistently trains new hires. It is considered a component of a lean and continuous improvement approach. Companies that implement TWI have seen the time to develop new hires into productive workers cut in half, along with immediate reductions in rework. [TWI was originally developed by the US War Department during WWII to rapidly instruct workers who were supporting the war effort. Toyota built their production system on TWI.]

TWI has three core components:

1. Job Relations (JR): This element helps supervisors lay the groundwork for TWI by building trust, cooperation and positive employee relations. Establishing positive relationships paves the way for the other aspects of TWI – resulting in workers who care about doing their jobs properly and pre-empting problems before they emerge. The approach emphasizes teamwork, treating people fairly and with respect, giving constructive feedback and positive recognition, informing workers about upcoming changes, and engendering loyalty and cooperation.

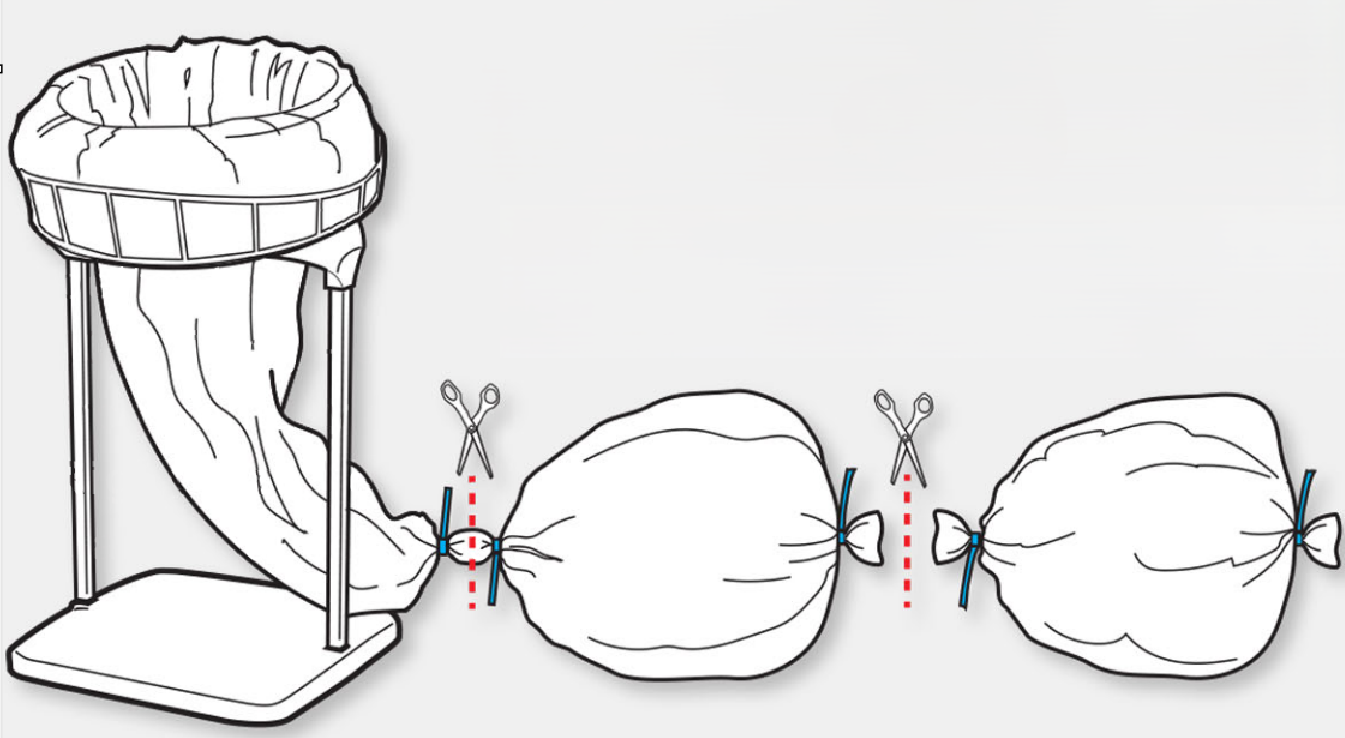

2. Job Instruction (JI): JI standardizes how jobs are taught and teaches supervisors how to train employees to perform a job correctly. The process enables faster, better and more consistent teaching of new skills, and allows supervisors to spend less time fixing the mistakes of new staff. Supervisors are taught to effectively break down a job for instruction into components. JI recognizes the best approach is to combine “showing and telling” techniques with “illustration and demonstration.” Typically, this employs a four-step process:

Step 1: Preparation – Describe the tasks

Step 2: Presentation – Show and demonstrate each step

Step 3: Test – Trainee is given opportunity to try the task during trial runs

Step 4: Follow Up – Coaching tapers off and the employee is given the opportunity to work on their own

[TWI was adapted by Toyota to teach workers in small increments as a two-way “show and tell” process. IHC uses the TWI in the same manner.]

3. Job Methods (JM): JM teaches supervisors how to improve the way jobs are done. The aim of the program is to reduce waste and help increase throughput of quality products. JM is based on small, incremental changes for continuous improvement, and like lean manufacturing, assumes that effective improvement ideas often come from the people on the floor performing the work. [Brackets and Italics ours]

TWI establishes trust-based relationships, and then gives supervisors the structure to become effective trainers. It helps supervisors to quickly and consistently train new employees, partly by establishing the best standard way to teach people to do their jobs, and then helps workers identify more efficient methods. Ultimately it also helps cross-train all existing employees, as standardized training extends beyond supervisors to the entire team. TWI reduces cost by eliminating mistakes and improving safety, and it helps managers and supervisors adopt effective leadership behaviors.

Source: National Institute of Standards and Technology (NIST)

See also: https://en.m.wikipedia.org/wiki/Training_Within_Industry