Applying Lean to Cleaning to Add Value

by Perry Shimanoff

Lean is about reducing waste, standardizing for flow and consistent outcomes, and adding value. It involves a systems approach to quality based on the teachings of Dr. Deming, perhaps best demonstrated by the Toyota Production System (TPS) as a way to build reliable, innovative cars; a method emulated by other car and even aircraft makers to add value and stay competitive.

Key #1: Reduce Waste, Add Value

Lean’s focus on minimizing waste, first embraces the axiom, “the mind is a terrible thing to waste” and second, avoids wasted task or cycle time.

As explained in the book, The Toyota Way, Toyota’s philosophy is to take a long-range view of success, looking past short-term financial goals, and investing in workers so they “thoroughly understand the work, live the philosophy, and teach it to others.”

Mike Joyce, a lean management expert at Lockheed Martin, noted: “So [just] what is the strategic significance of Lean…? I want us to invest in the knowledge in people’s heads. I’m not asking for capital or computers. I’m asking for an investment in people…” [brackets ours]

Engaged workers — whose minds and hearts are on-the-job and not “wasted” — add value to the customer by having an active share in product quality and improvement.

In the book, Competing Against Time, the authors identify two rules relevant to reducing cycle or wasted time:

5% Rule: Delivering a service may require only 5% of the elapsed time commonly taken.

25/20 Rule: A 25% reduction in elapsed time may double productivity and cut costs 20%.

Investing in workers through ongoing training and development, and providing them labor-saving equipment and proper training to use it, reduces wasted time and energy, while optimizing process, efficiency, and results.

Key #2: Standardize, Add Value

Standardizing is another key ingredient to success.

Just as a car assembly line builds a reliable, affordable car by a standardized step-by-step process — cleaning in a standardized, stepped way builds a consistently clean building within budget.

Just as a car has no unnecessary parts, every cleaning step or “part” should add value (e.g., remove soil) not subtract it (e.g., add soil). Vacuuming floors may add value by removing soil, while sweeping may subtract value by leaving much of it behind. Cleaning by wet-vacuuming floors may add value by removing soil suspended in liquid; mopping floors may subtract value by leaving dirt and moisture on floors and in grout, along with odor-causing bacteria.

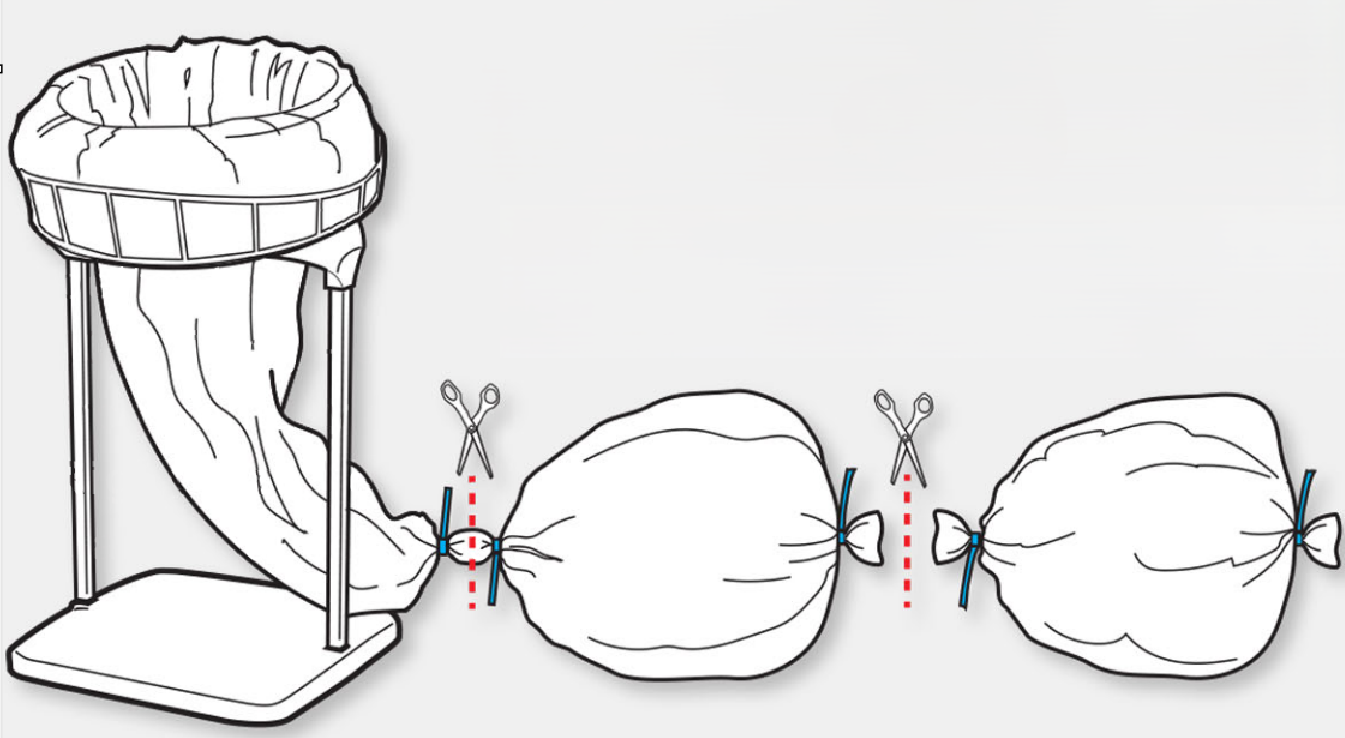

Removing trash, dirt, pathogens — and putting things in proper order — are all steps in a “lean” cleaning process built on best practices.

Key #3: Achieve Flow, Add Value

Lean eliminates wasted steps and promotes “one-piece flow” — e.g., no interruptions.

Specialists with multipurpose tools and training can complete specialties such as restroom cleaning in a single process. This saves time and energy, while producing excellent results and value for the customer.

About the Author

Perry Shimanoff is a principal of MC2 (Management and Communications Consultants) and a CMI Certified Custodial Master Trainer.

Thank you for taking time to learn this information.

Please read the post above and use the three flashcards below the flashcard instructions to internalize the key points.

It is okay to re-read the post and flashcards (front and back) to ensure you

know the material.

Then at the end, if possible without looking at the back of the cards,

put the answers in your own words

and submit for review.